Pipeline Inspection

Introduction

The oil and gas inspection industry operates according to stringent standards that primarily strive to keep equipment running efficiently while maintaining workplace safety. Pipeline pigging has become an important part of pipeline maintenance programs. Specific pigs have been developed to perform different functions such as drying, cleaning, batching, gauging, applying films etc.

Inspection of oil and gas pipelines starts with first step which is prepare the pipeline to be clean before running the inspection tools. Cleaning pigs are generally designed to push any loose material through the pipeline and to apply a mechanical force between the pig and the pipe wall surface to remove debris that can be easily removed. They typically will be composed of a combination of a wiping/sealing surfaces made up of discs, cups or foam with brushes mounted on them made out various materials. Figures below shows the cleaning tools that used to clean and prepare the pipeline for inspection

Integration of the oil and gas pipeline

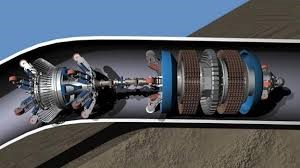

our company will provide the tools that has ability to integrate the sizes of the oil and gas pipelines which are various from 10” to 42”, for this purpose we have different tools to inspect the pipelines and detect the metal loss, these tools include the ultrasound pig and manga scan high resolution intelligent pig. the critical metal loss needs to be immediate repaired will be detected during the inspection, also any dent in the thickness of the pipelines will detected and recorded. Our team will work according to the standards to bring the best quality of results in terms of cleaning the pipelines until the step of inspection using intelligent pig. After the inspection has completed and confirmed all the data were recorded by the inspection tool then a software will be used to interpretation the data recorded and issue the final report with the recommendation of which parts of the pipelines needs to be replaced in order to continue the operation.

— Robert P., Field Operations Manager

Key Features:

- Onshore and offshore drilling capabilities

- Directional, horizontal, and vertical well drilling

- High-precision gas well drilling and completion

- Advanced mud systems and pressure control